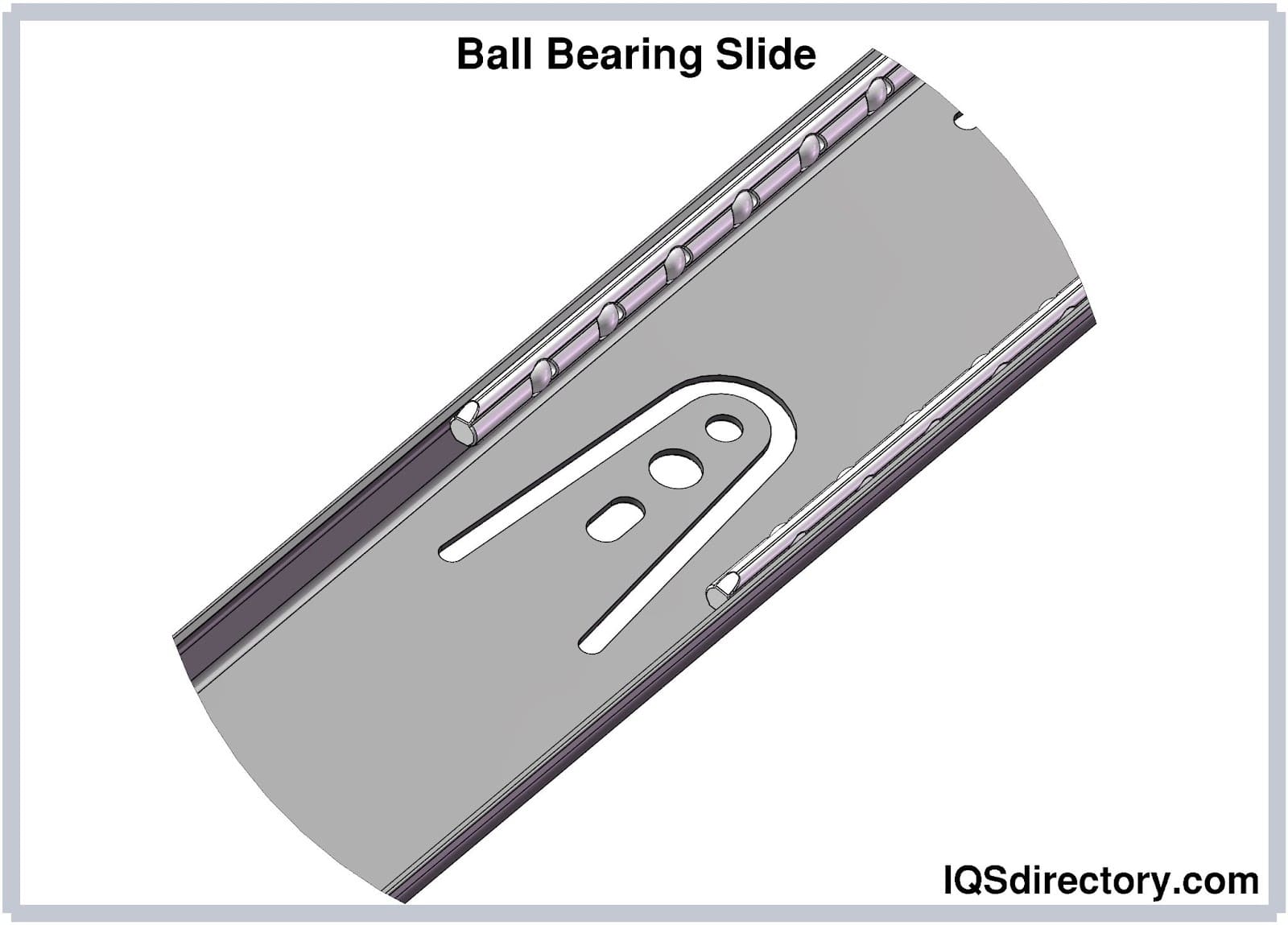

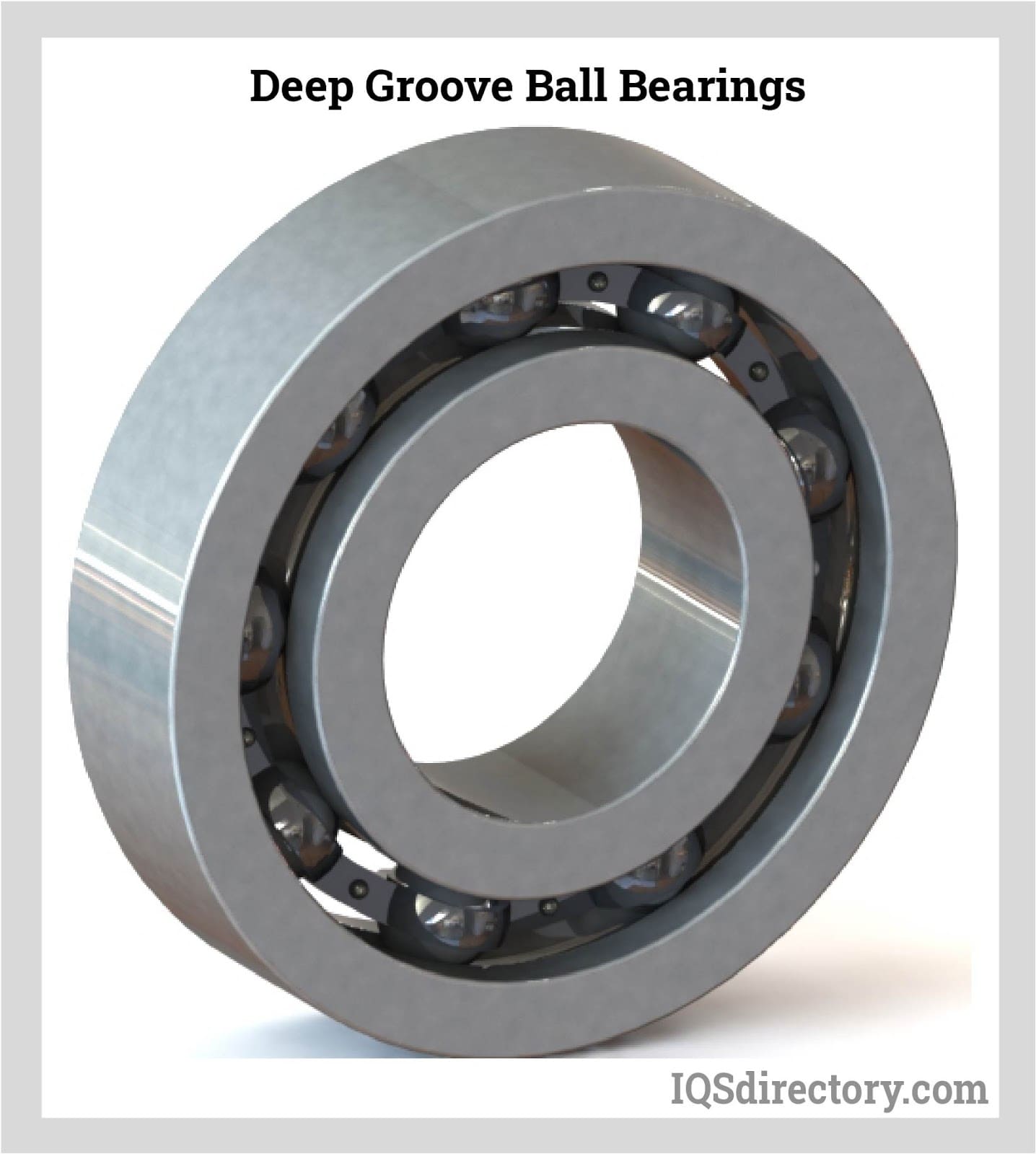

Ball bearing slides are a subcategory of linear slides used in areas where two surfaces move against each other to produce a very smooth and low-friction movement. The ball slides use metallic spheres made from durable materials like galvanized or regular steel and aluminum found in a confined rail system. Read More…

Del-Tron is a linear slide manufacturer/distributor of ball bearing slides, crossed roller tables, roller slides, multi-axis positioning stages, xy tables, motor-ready lead screw stages & crossed roller rail sets.

When describing Tusk Direct, a linear slide distributor, products such as linear motion components, roller tables, ball & crossed roller slides, dovetail slides, bushings, multi-axis positioners & motor ready lead screw actuators, come to mind.

Isotech is a distributor of precision linear motion components: air cylinders, linear actuators, linear slides, ball slide assemblies, crossed roller slide assemblies, re-circulating ball slide guides. We can supply standard or high precision products in either English or metric, all with the convenience of on-line ordering. Our parts are ready for installation right out of the box.

Established in 1967, Velmex makes manual & motor driven dovetail slides, open frame tables, twin rail slides, rotary and XY stages. Choose hand, lead screw or belt drive.

More Ball Bearing Slide Manufacturers

The moving component is attached to the rail system, and the balls enable smooth motion of the component.

How do Ball Bearing Slides Function?

Ball bearing slides are used to reduce friction and allow smooth movement between moving bodies without damaging the object. They are commonly used in sliding drawers. In sliding drawers, the sliding balls move in the metallic tracks between the desk and drawer body, not allowing them to come into contact.

Upon reaching the endpoint of the drawer opening extent, the intermediate component slides until it fully opens and cannot open any further.

Ball Bearing Slides Considerations

Ball bearings are an important innovation, and careful consideration must be taken when deciding to use one. The weight of contents to be handled is a very important consideration.

Cabinets and desks use different slides because some are best suited for heavy filings and books, while others are small, simple, and meant for lightweight paperwork and office equipment.

The use of wrong slides results in easy jamming, sticking and even the wearing out of furniture, which results in further unplanned expenses.

Types of Ball Bearing Slides

There are several types of slides differentiated by the mechanism they use. Ball bearing slides are commonly used in drawers for desks and cabinets; the two most-used types are ball bearing drawer slides and soft close ball bearing slides.

Ball Bearing Drawer Slide

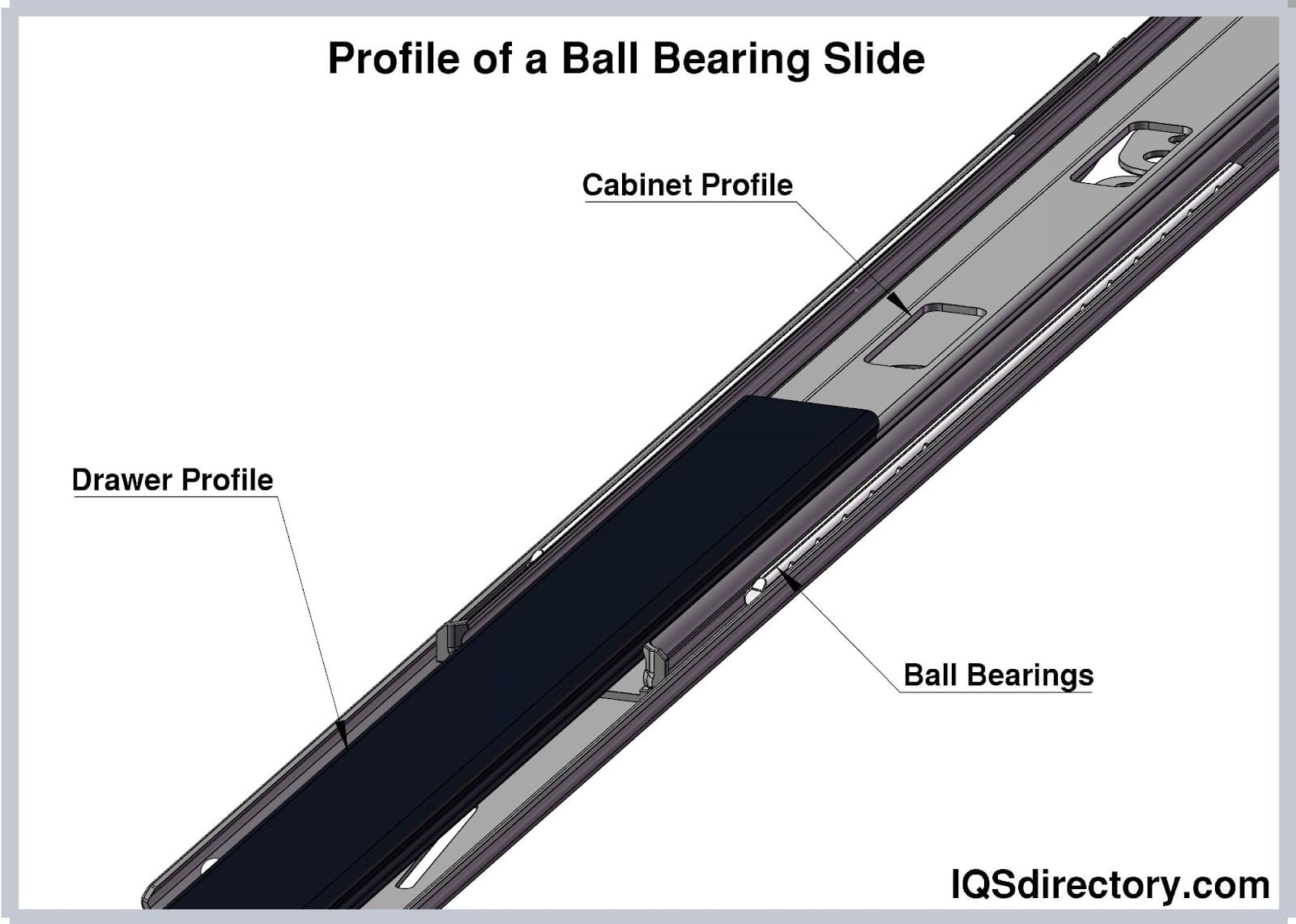

Ball bearing slides allow smooth movement through free-rolling ball bearings that allow lateral movement. They consist of a cabinet body component, an intermediate member, and the drawer. The drawer attaches to the intermediate member, which is attached to the cabinet or desk member.

The intermediate member interfaces with the ball bearings; one interfaces with the grooves of the cabinet, and the other in the grooves of the drawer. The drawer moves when in use, sliding over the ball bearings. When the limit is reached, the intermediate member slides along the ball bearings itself until the whole set is fully extended.

Soft Close Ball Bearing Slide

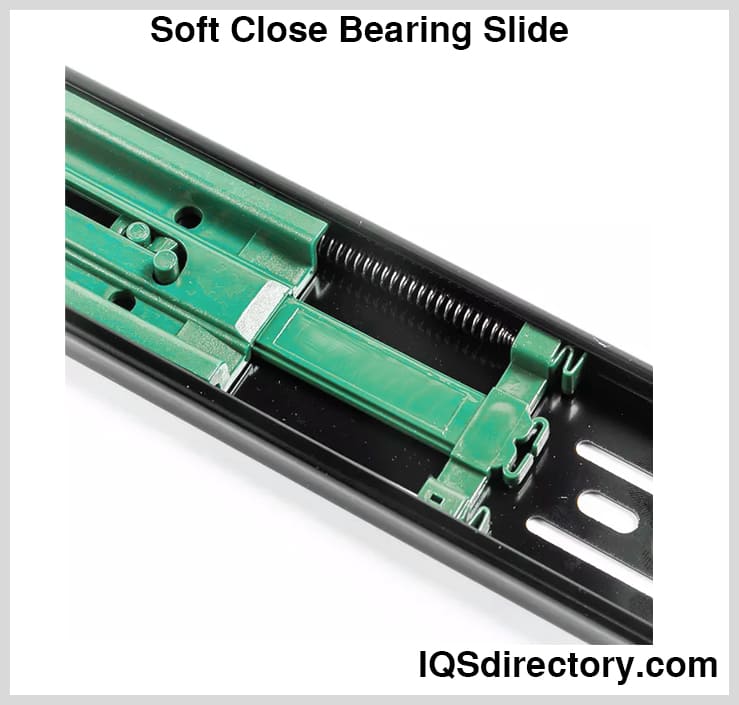

Soft close bearings are next-generation ball bearings that allow drawers to close silently and smoothly. They have a functionality similar to that of the ball bearing slide, but upon closing, another installed soft close mechanism automatically takes the drawer into its closing position.

It uses hydraulics which controls the moving parts so they can move at a steady pace. The soft close mechanism is equipped with a spring and a piston (hydraulics system) that control the closing of the drawers. A gentle push on the drawer leaves it moving by itself until it closes without making any noise or damaging contents inside.

Applications and Benefits of Ball Bearing Slides

The applications and benefits of ball bearing slides include:

Applications of Ball Bearing Slides

Ball bearing slides are commonly used in a variety of day-to-day applications. Typical examples are in robotics and instrumentation constructions.

Extending parts and joints are made from smooth-moving ball bearings.

Desk drawer slides make use of ball bearings as they can be used to support heavy office workloads without failing.

Benefits of Ball Bearing Slides

The reduced friction on furniture and equipment through ball bearing slides greatly improves the general efficiency of machines. In addition, maintenance costs are greatly cut due to the smooth moving of parts which do not even harm the furniture. Ball bearing slides also promote a quieter workplace or kitchen as there is no noise of sliding and banging drawers.

Choosing the Correct Ball Bearing Slide Supplier

To make sure you have the most productive outcome when purchasing ball bearing slides from a ball bearing slides supplier, it is important to compare at least five suppliers using our ball bearing slides directory. Each ball bear slide supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each ball bearing slide company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple ball bearing slide companies with the same message.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services