A roller table is a piece of high-precision equipment often moved by electrical or mechanical driving mechanisms, allowing massive loads to be moved with ease. Another synonym of roller tables is positioning stages, defined as motorized linear slides with precise rail sets supporting cumbersome loads at low friction. Read More…

Del-Tron is a linear slide manufacturer/distributor of ball bearing slides, crossed roller tables, roller slides, multi-axis positioning stages, xy tables, motor-ready lead screw stages & crossed roller rail sets.

When describing Tusk Direct, a linear slide distributor, products such as linear motion components, roller tables, ball & crossed roller slides, dovetail slides, bushings, multi-axis positioners & motor ready lead screw actuators, come to mind.

Isotech is a distributor of precision linear motion components: air cylinders, linear actuators, linear slides, ball slide assemblies, crossed roller slide assemblies, re-circulating ball slide guides. We can supply standard or high precision products in either English or metric, all with the convenience of on-line ordering. Our parts are ready for installation right out of the box.

Established in 1967, Velmex makes manual & motor driven dovetail slides, open frame tables, twin rail slides, rotary and XY stages. Choose hand, lead screw or belt drive.

More Roller Table Manufacturers

What is a Roller Table?

Due to the high accuracy demanded when using roller tables, they are manufactured to withstand heavy loads, pull or push, and to be highly accurate.

They consist of an attached moving carriage and a linear base. Roller tables have roller slides with single or multiple axes with tables and shafts to maximize direction and control.

Roller tables are well known for their exceptional capability to carry loads and high accuracy. Roller tables are customarily designed based on load capacity, material, freedom of movement, and size of the intended use.

How Roller Tables Function

Roller tables consist of two or more slides enabling them to carry heavy loads. A screw drive is placed between the platform and base, creating a motorized linear slide. The slides consist of a moving platform and a base that allows manual movement with a secure locking mechanism.

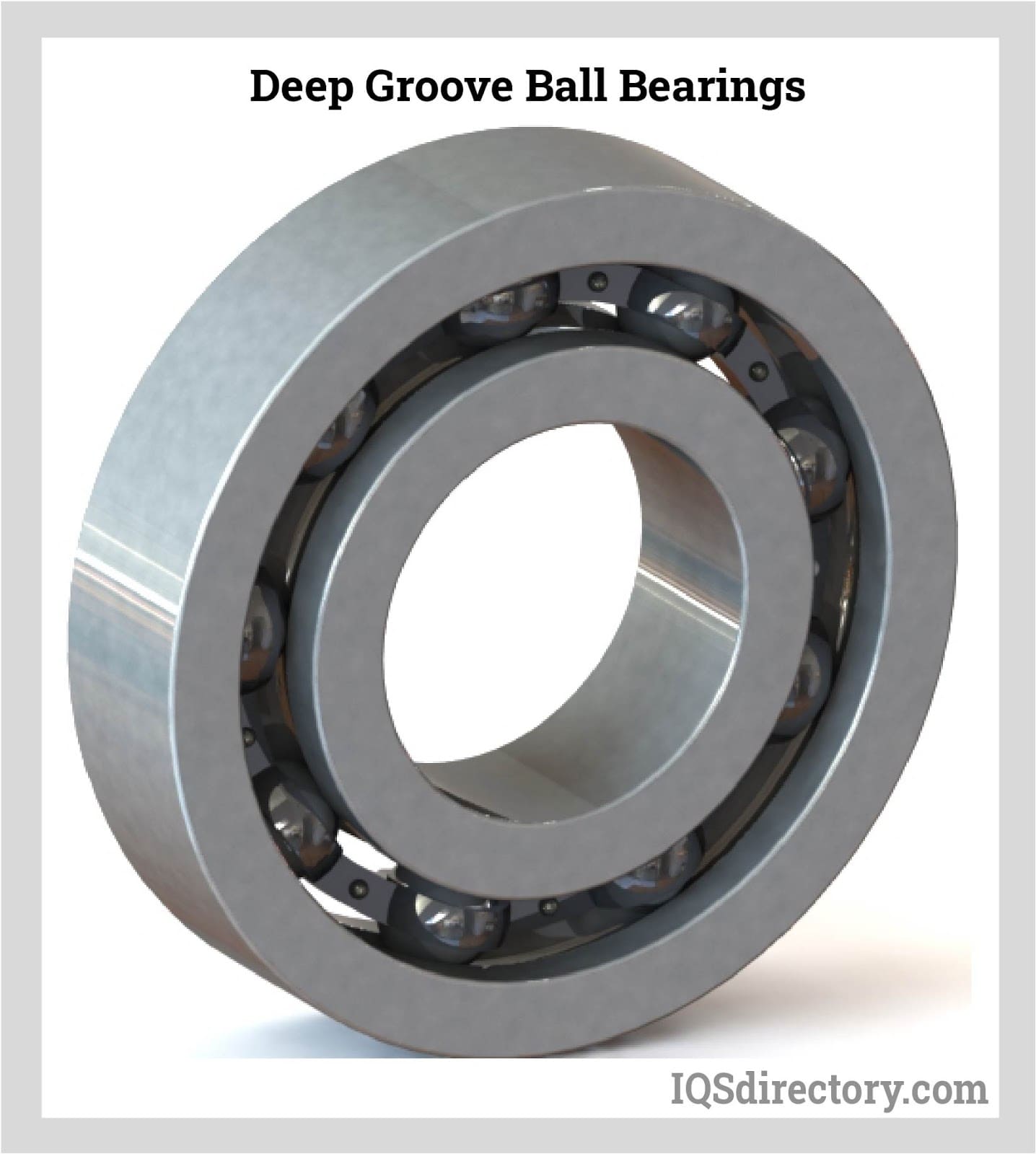

The platform houses roller bearings that allow low friction between the linear rails and the table or platform. Most use bearings; cylindrical bearings produce the least amount of mechanical noise.

Roller Tables Installation

A roller table has various ways in which it can be mounted in X, XY, or XYZ configurations in multi-axis linear position and motion. Shock absorbers or rubber bumpers are used to stop the slide table, and stroke adjusters can be used for precision positioning.

To reduce errors associated with the system, air-bearing slides for roller tables can be installed where there is pressurized air controlled between the platform and the base.

A roller cage can be installed on the table to help prevent slips during movement and balancing loads. In some installations, shields and covers are attached to prevent dust from penetrating the sliding base and platform, hindering motion.

Types of Roller Tables

The different types of roller tables include:

Low Profile Roller Tables

Low-profile roller tables are highly accurate slide tables with adjustable preloading. They can withstand force in all directions due to the crossed rollers at an angle of 45 degrees. Low-profile roller tables have a straight line accuracy of 0.0001 inches per 1 inch (or 0.0025 mm per 25 mm) travel.

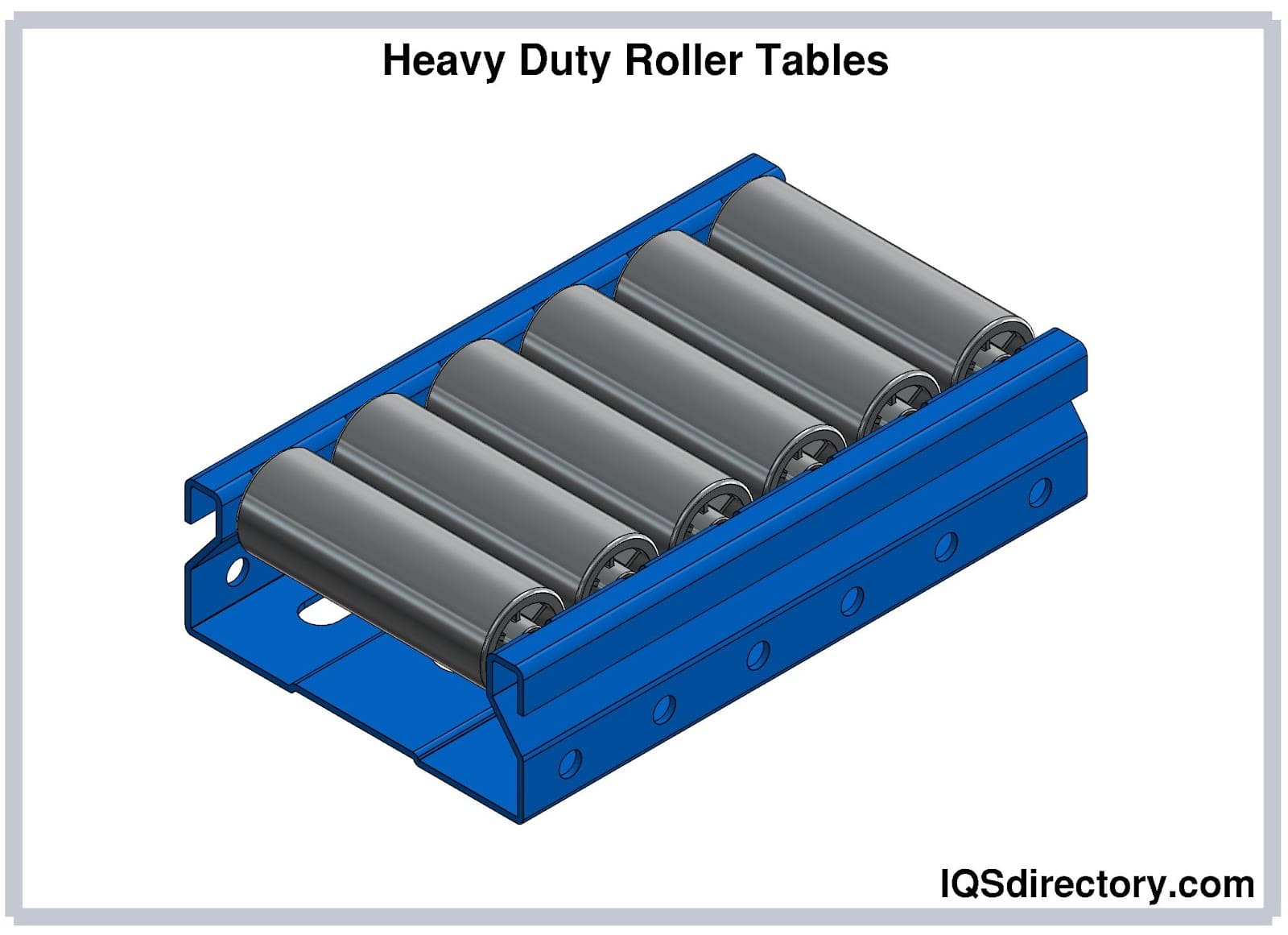

Heavy Duty Roller Tables

Heavy-duty roller tables are used to lift heavy packages and cartons. They are useful in the setup of conveyor lines in shipping departments, assembly areas, and warehousing activities.

They comprise hex-shaft axles for additional capacity and strength, variations of curves such as 30, 45, 60, and 90 degrees, and couplings bolted together for connections.

Crossed Linear Rails Tables

These roller tables provide greater control and precision with the capability of carrying high loads. Crossed linear roller tables can be found in steel construction and other choices for application design. Mounting holes in aluminum crossed roller tables are available in metric and inch mounting.

In cases of high acceleration and deceleration or vertical application, there is a need to consider anti-creep crossed tables. Roller cage and rail design take care of roller cage slippage or migration in high vertical applications and speed.

Crossed linear roller tables are factory preloaded and ready to install. They provide extremely precise linear motion with relatively low friction by using crossed roller bearings.

Applications and Benefits of Roller Tables

The applications and benefits of roller tables include:

Applications of Roller Tables

Roller tables are used in:

- Fiber optic systems

- Material handling industries

- Industrial automation equipment

Benefits of Roller Tables

A roller table is a cost-efficient method of moving equipment and a cheaper way of improving the efficiency of a system within an operation.

- Simple design manufacture and operation

- Moves heavy loads using very small power output

- Have high accuracies: 0.0001 inches per 1 inch (0.0025 mm per 25 mm) with loads of 2600 lbs (1179 kg) and excess

- Lightweight

- Ready for installation from the box due to factory preloading

Choosing the Right Roller Table Manufacturer

To ensure you have the most positive outcome when purchasing roller tables from a roller table manufacturer, it is important to compare several companies using our directory of roller table manufacturers. Each roller table manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each roller table company website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple roller table companies with the same form.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services